Toyota doesn’t just meet the bare minimum. We go beyond what is expected and put concern for our operators at the forefront of our work. At the core of the many safety elements built into every Toyota forklift is our proprietary System of Active Stability™ (SAS). This game-changing and industry-

leading forklift technology minimizes the likelihood of tip-over, reducing risk for operators and those around them. In addition, Active Mast Control detects the load weight and the mast height to decrease the chance of a load spill, providing even more safety. And because we realize a safer forklift is only part of the equation, we’re also proactively engaged in operator safety training. Toyota dealers offer comprehensive training materials and programs to help companies meet all North American safety regulations.

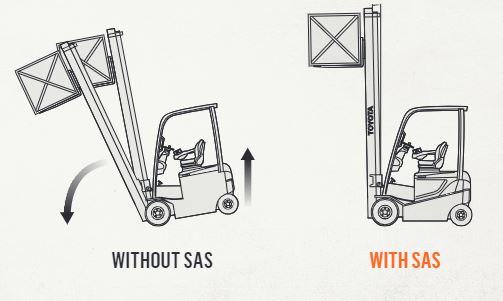

TOYOTA’S SYSTEM OF ACTIVE STABILITY™ (SAS)

Increasing both lateral and longitudinal stability, our exclusive SAS is a direct adaptation of automotive

traction control technology. When the system detects a situation that could lead to instability, it instantly

engages the swing lock cylinder to stabilize the rear axle — changing the forklift’s stability footprint from

triangular to rectangular in shape. The system also includes two other components, active mast control

and auto fork leveling, to increase stability and help avoid overturns. Because everyone deserves this extra measure of safety, SAS isn’t an option or an upcharge. It comes standard on every 4-wheel Toyota model that can accommodate it*. * Design and availability varies by model.

** Swing lock cylinder concept shown for reference.

SAS ADVANTAGE

When it senses the potential for instability, SAS instantly engages the swing lock cylinder to stabilize the rear axle, creating the lateral stability needed to help reduce risk of tip-over.

AUTOMATIC FORK LEVELING

SAS Automatic Fork Leveling Control adjusts the mast so that the forks are level with the ground for ease in retrieving pallets at high levels.

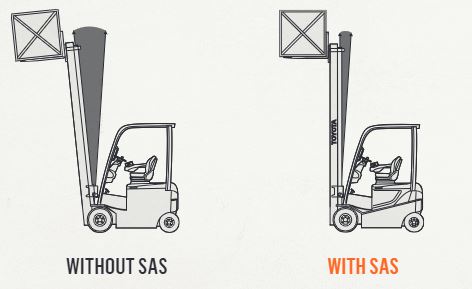

ACTIVE MAST CONTROL

Sensing the load weight and mast height, the rear tilt speed control governs the mast’s reverse tilt speed to decrease the chance of spilling unsecured loads or tipping the forklift backward.

Forward Tilt Angle Control automatically overrides the operator’s manual control, limiting the forward tilt of the mast and making it more difficult to spill a load. Or worse, tip the forklift forward.